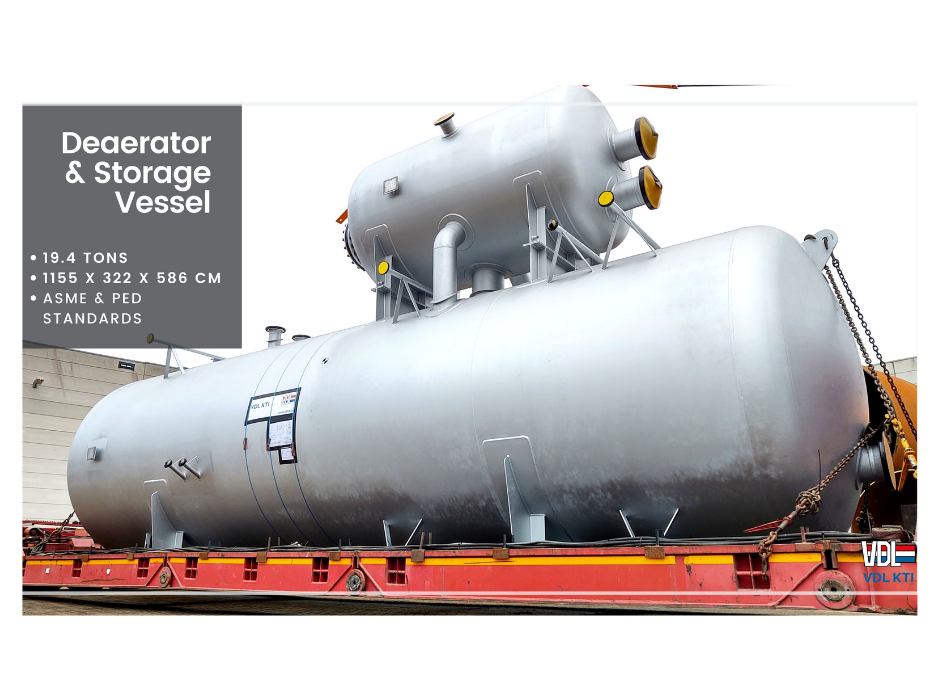

VDL KTI kicks off the new year with successful completion of a Deaerator and Storage Vessel

The task of VDL KTI for this project includes engineering, fabrication, QA/ QC and delivery of deaerator and storage tank according to ASME and PED standards. A deaerator is a device that removes dissolved gases, such as oxygen and carbon dioxide, from liquids like water. The treated liquids then fall into a storage tank below the deaerator.

Carbon steel, the main material used for the shell in this project, has full traceability with European certificate EN 10204 3.1. Starting from material receiving inspection, numerous inspections were executed and passed throughout the entire project, including visual inspection, radiographic examination, magnetic examination, penetrant examination and pressure testing. By paying attention to every stage of the process of production, we’re able to ensure the highest quality of our product.